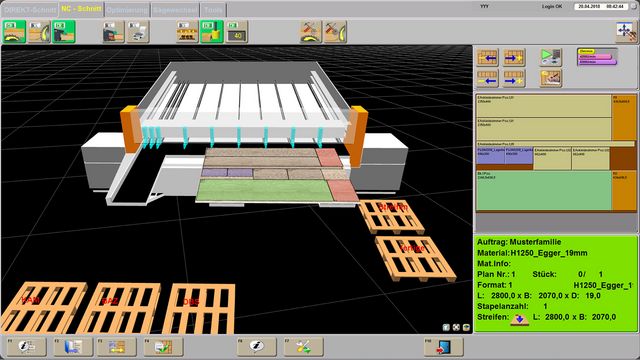

HOLZ-HER TECTRA 6120 dynamic: Completely prepared for dynamic charging

The TECTRA 6120 dynamic pressure beam saw from HOLZ-HER is distinguished by its absolute cutting precision and comprehensive basic features. Simple linkage to automated panel storage facilities as well as uncomplicated data transfer from conventional branch software or software from other suppliers is a further highlight of the TECTRA 6120 dynamic, allowing implementation of custom concepts with short amortization times for handicraft and industrial businesses.

Thanks to its high acceleration values and feed rates, the TECTRA 6120 can process even large quantities of panels rationally. This versatile saw is available with various cutting lengths and cutting widths, allowing it to be adapted to highly varying applications as a custom solution.

Different requirements - different prices

The price of a HOLZHER machine is just as individual as your requirements are. Therefore, let us discuss briefly what is most important to you – you will then receive our preliminary, non-binding quote.

Personal advice – for higher productivity and greater efficiency

Together with your HOLZHER expert you will find the ideal machine for your requirements. Simply submit the completed form, and your local HOLZHER expert will be happy to discuss all further details with you.

Here is what the HOLZ-HER TECTRA series offers

Here is what the HOLZ-HER TECTRA 6120 dynamic offers

- Prepared for charging solutions

- Saw Blade Protrusion up to 95 mm

- Sawing Unit: up to 15 kW

- Cutting Lengths: up to 4,400 mm

- Cutting Widths: up to 6,500 mm

Technical Details

Control Center

A perfectly designed workplace provides the basis for efficient, non-fatiguing work. With the 21.5" control terminal HOLZ-HER panel cutting saws satisfy all requirements placed by machine operators. The ergonomically adjustable rack offers space to position up to two printers, scanner, keyboard and mouse where they are located perfectly for the operator.

- The control center with large multi-touch 21.5” full HD monitor with 16:9 format guarantees maximum clarity with real time 3D graphics and full graphic finalization help.

- A cordless mouse and QWERTZ or QWERTY keyboard are provided to meet the requirements in the specific county.

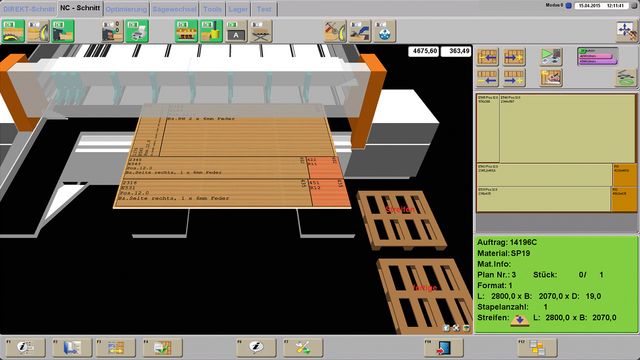

The CUT CONTROL 2 control package

The high performance software package for HOLZ-HER industrial saws

The control is decisive for the power output of a state-of-the-art pressure beam saw. All HOLZ-HER panel cutting saws are equipped with our CUTCONTROL 2 and the preinstalled EASY-PLAN and OPTI-CUT software packages.

Everything at a glance:

- The self-explanatory graphical user interface ensures that your employees can start operating the machine quickly and properly without any major training.

- The optimized information display ensures maximum "clarity" (buttons and features not required are hidden).

- EASY-PLAN optimization software preinstalled at the factory.

- Individual jobs can be assigned a priority at any time, job programming parallel to cutting.

- Graphic 3D user interface for intuitive operation and machine sequence functions for NC cutting.

- Program-controlled measurement of reference dimensions when saw blade is changed.

- Information display indicating running meters for main and prescoring saws.

- Individual adaptation of function and parameter settings.

- Operating states, service and maintenance intervals as well as separately programmed energy management are displayed in real time.

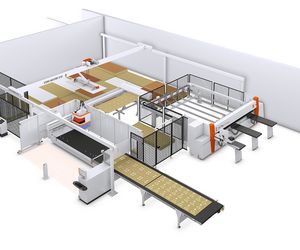

Profitable, state-of-the-art charging solutions

Prepared for profitable, state-of-the-art charging solutions

HOLZ-HER storage systems offer fully automated and intelligent processes as well as highly efficient use of available storage space. Sophisticated fully-integrated software with chaotic storage management increases production capacity enormously. From manual charging to automatic panel handling from a horizontal storage facility. The TECTRA 6120 dynamic is perfectly prepared for mature solutions as well as all sizes of shops and all types of applications.

- Extended cutting width of 6,500 mm - allows the next panel or next stack of panels to be fed to the saw simultaneously while cutting is in progress. This eliminates waiting times and guarantees cutting cycles at maximum speed. It also allows large panels to be cut crosswise.

- Liftable workpiece clamps - with linear guide allow compensation of irregularities in panels/stacks. The clamps are moved automatically to their highest position at the rear area of the machine for prestacked panel stacks. This allows the clamps to move over the stack of panels, grip the stack and move it toward the cutting line.

- Two standard longitudinal alignment units - for high speed, automatic alignment of panels or stacks.

Other applications can be selected as options.

- Additional roller tracks - prevent remnants or thin panel material from sagging.

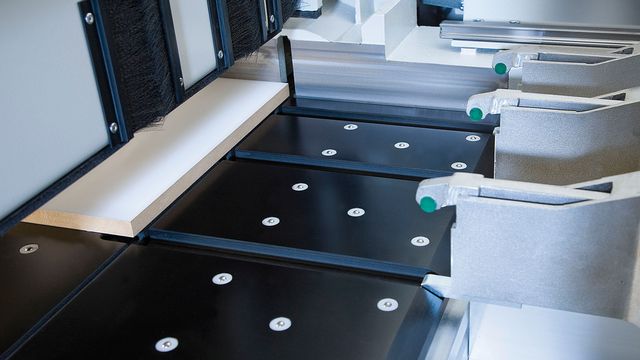

Solid air cushion tables

High functionality – perfect ergonomics

The TECTRA meets the highest demands in terms of its technology and equipment.

- Air cushions for the machine table protect the workpiece during handling. A powerful fan provide a large area air cushion, which allows heavy stacks of panels to be moved easily.

- The air cushion tables never distort, even under heavy panel packages. Another optional feature includes long panel formats up to 2,400 mm.

- The support tables can be moved for workpiece with small dimensions or to obtain additional space (optional).

Cutting line closure devices

The cutting line closure devices prevent trim cuts or narrow strips from falling down and jamming in the saw slot and the saw carriage. The strips can be easily removed by the operator directly after the cut. The cutting line closers are all individually controlled and close after the saw blade has passed by. The process takes place automatically via the control system.

Twin Press - Side alignment

The rubberized side pressure rollers in front of and behind the cutting line are pre-positioned by the optimization and lower directly in front of the workpiece. Even the last cut is neatly stopped at the angle ruler. This creates maximum performance when cutting the panel strips to length. The double side pressure is guided by the solid linear guides.

Line laser for cutting line

The Visible Cut Line uses a laser beam to indicate the exact cutting line. This also allows cuts according to a manual sketch to be positioned and cut perfectly. Naturally this device also provides a major advantage when cutting real wood (e.g. edging).

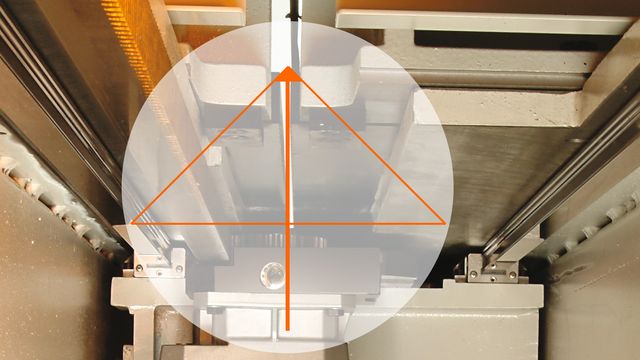

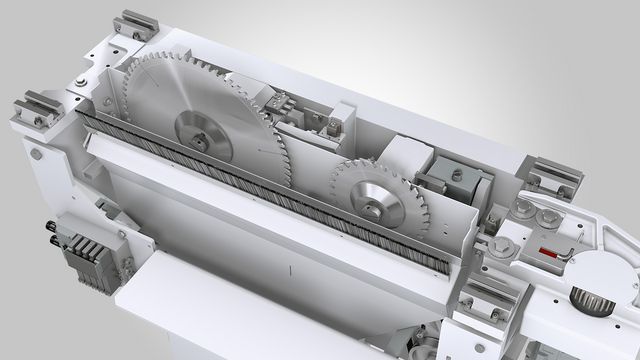

The sawing unit of the TECTRA series

High Power – Extremely Smooth Operation

Optimized, torsionally rigid cast design, as well as use of linear guides guarantee perfect cutting results. Perfect power triangle at the cutting line for permanently ideal sawing performance thanks to sophisticated design of the sawing carriage guide and maintenance-free rack-and-pinion drive.

- Main sawing motor - Equipped as standard feature with powerful 11 kW motor (7.5 kW on classic). For even more power the TECTRA can be equipped with an optional high power 15 kW drive (11 kW on classic).

- Max. saw blade protrusion - 95 mm (82 mm on classic) for high power stack cuts or quick raw cuts

- Sawing carriage - with a saw blade diameter of 380 mm (350 mm on classic), the automatic, infinite cutting height adjustment ensures optimum saw blade protrusion for cleanly cut edges.

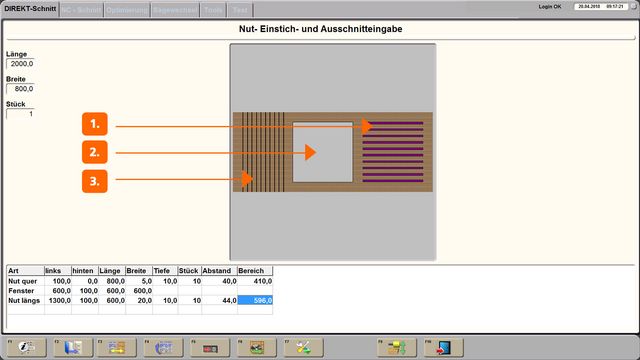

- Motor-driven groove height adjustment - adjustable groove depth from 0 - 30 mm programmable on control and optimization.

- Bidirectional grooving program (FCM) Fast Cut Mode - Ensures extremely short cycle times for grooving, whereby a groove is also cut as the sawing carriage moves back (optional on classic).

- Automatic cutting length limitation - A proximity-type optical feature recognizes the end of the workpiece - eliminating unnecessary sawing carriage travel, especially for manual cuts.

- Optimized automatic cutting length feature - The sawing carriage is controlled by the optimization feature - the sawing carriage is prepositioned beneath the panel, the start and end of the cut are calculated, paths without cutting are traversed at maximum speed.

- Electrically adjustable prescoring saw - Allows simple and perfect adjustment of the prescoring saw on the monitor, in the shortest possible time, with minimum effort.

- High performance postforming unit (optional) - for tear-free cutting of postformed and other edges up to a panel thickness of 50 mm.

- Quick-change clamping system for main and scoring saws - ensures precisely clamped saw blades and extremely short standstill times for changing saws.

Freely programmable rip fence

Stable, welded construction with precision, hardened linear guides ensure precise, smooth running. Direct rack-and-pinion drive and proximity-type sensor for absolute dimensions guarantee maximum positioning accuracy. Valid. Floating-type workpiece clamps compensate for tension in the panel stacks toward the top.

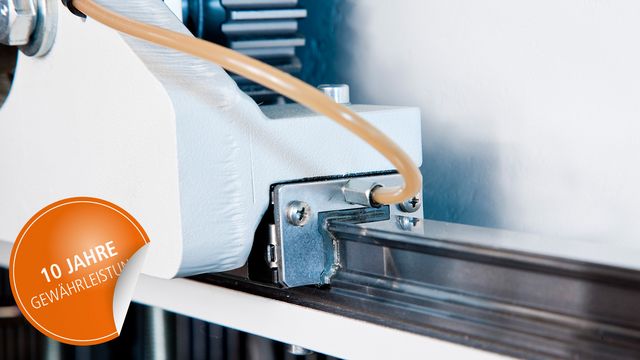

The 'power' workpiece clamps

Perfect hold - HOLZ-HER double-finger workpiece clamps

Three double-finger workpiece clamps in the stop area allow narrow strips to be cut simultaneously with maximum stability. The floating type clamps compensate for tension in the panel stack using a linear guide. For precise cutting on unveneered workpieces, optional controlled trimming stops are available.

Remnant cutting device for division without remnants. The clamps retract into the grooved pressure beam. Panels can be used completely during processing.

Remnant cutting device integrated into the pressure beam

Remnant cutting device for division without remnants. The clamps retract into the grooved pressure beam. Panels can be used completely during processing.

Dust Control – for program-controlled evacuation

(1) The front evacuation flaps are active during transverse cutting.

(2) The rear evacuation flaps are active during longitudinal cutting.

The cutting position recognition feature optimally controls all evacuation openings in the pressure beam. This always ensures maximum evacuation power directly at the saw blade, keeping your machine table free at all times. Evacuation openings not required are closed automatically - can, however, be adapted manually on the control to ensure your machine table is always clean.

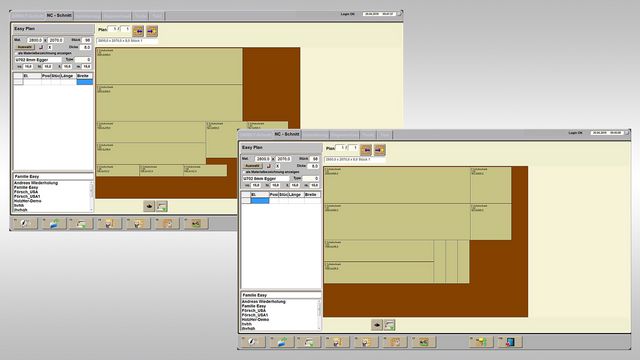

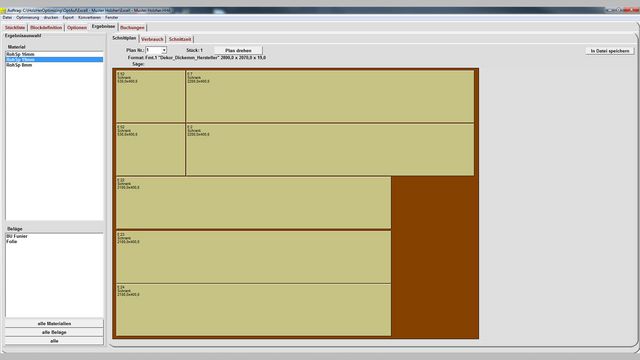

Optimization module EASY-PLAN

EASY-PLAN – the name is the program

The EASY-PLAN optimization software installed as a standard feature provides all functions, such as:

- Entry of material data and parts list data

- Job summary

- Cutting plan survey for optimized jobs (representation at one level)

- Material-related result display in graphic form.

- Display provides information on required material formats, panels and remaining formats per job.

- Complete jobs can be reset and booked back into the parts list at any time.

The material data entry provides information on length, width and thickness of the material, quantity present in stock, turnability in consideration of grain pattern, material designation, type number and trimming. The parts list data includes the element number, position number, quantity, length and width.

Optimization module OPTI-CUT

OPTI-CUT – makes your work even easier

OPTI-CUT serves for laying out, managing and optimizing jobs. The integrated OPTI-CUT optimisation software can also be purchased as a combination package – with machine and office version (OPTI-BASE).

- The software supplies current job information for NC cutting.

- An additional module imports parts lists from user programs.

- Simple configuration of all system settings

- Material-related result display of optimized parts lists in graphic form

- Layout and management of edging lists with predefined edging recommendation lists

- Defined cutting length adaptation from the software reduces cycle times decisively.

Optimization module OPTI-PRO

OPTI-PRO – premium optimization

The professional optimization in one complete package with a variety of additional modules. This optional optimization package for sawing software is equipped for high speed data input as well as simple transfer of cutting data from branch or ERP programs via CSV interface. For example, the OPTI-PRO can calculate cutting times and take over edging material management for you. Naturally, the block part module also allows representation of furniture fronts. Other high performance features include:

- Job management

- Material and coating management

- Data migration

- Configuration

- Display of results

- Material booking

- Edging and grooving entries

- Use of cuts

- Block part optimization

- Edging calculation, data migration

- Export of all data

- Cutting time calculation

- Label printout in office

- Filler parts

- Bar optimization

- Collective jobs

- Second license

Technical Details

Maximum efficiency with Holz-Her machine networking

HOLZ-HER realizes your production ideas within 20 minutes from the first mouse click to finished furniture with seamless machine networking.

Energy savings made easy

The intelligent ECO MODE energy management for HOLZ-HER pressure beam saws not only helps preserve our environment - it also saves you money.

References

Further information

Brochures

Simple, fast and sustainable: more details in a downloadable PDF document.

Brochure TECTRA series (PDF, 3 MB)